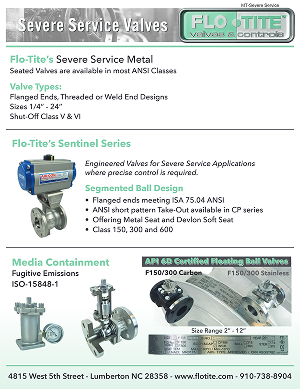

MT Severe Service Valves 2025

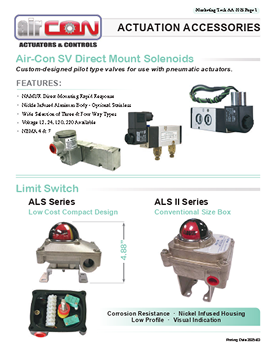

AirCon Actuator Video Fail Close to Fail Open

How to mount Aircon actuator SR/DA.075 to Flo-Tites multichoice series.

Steps on changing out repair kits in A Flo-Tite SF150 SS and CS

Steps on changing out repair kits in A Flo-Tite RF15/30 SS and CS

How to change repair kits in Flo-Tite’s F150

How to change repair kits in Flo-tite’s 300/ Multi Choice series

Steps on reversing actuator

2 in valve acceptable leak

3 inch Carbon pass

6 inch fail

6 inch pass

8 inch fail

8 inch pass

RV Valves in inventory

RV Valves in inventory 2

Valves in inventory Tagged wrong

RMA 5231 nitrogen gas test

A look at Flo-Tite’s manufacturing facility in Lumberton North Carolina.

MVI 3110

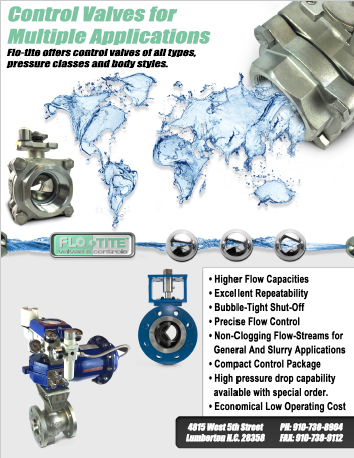

Flo-Tite Valve and Controls Globe Control Valve

Flo Tite’s Valves and Controls New Ball Valves and Control Valves

Max Seal Butterfly Valve Manufacturing

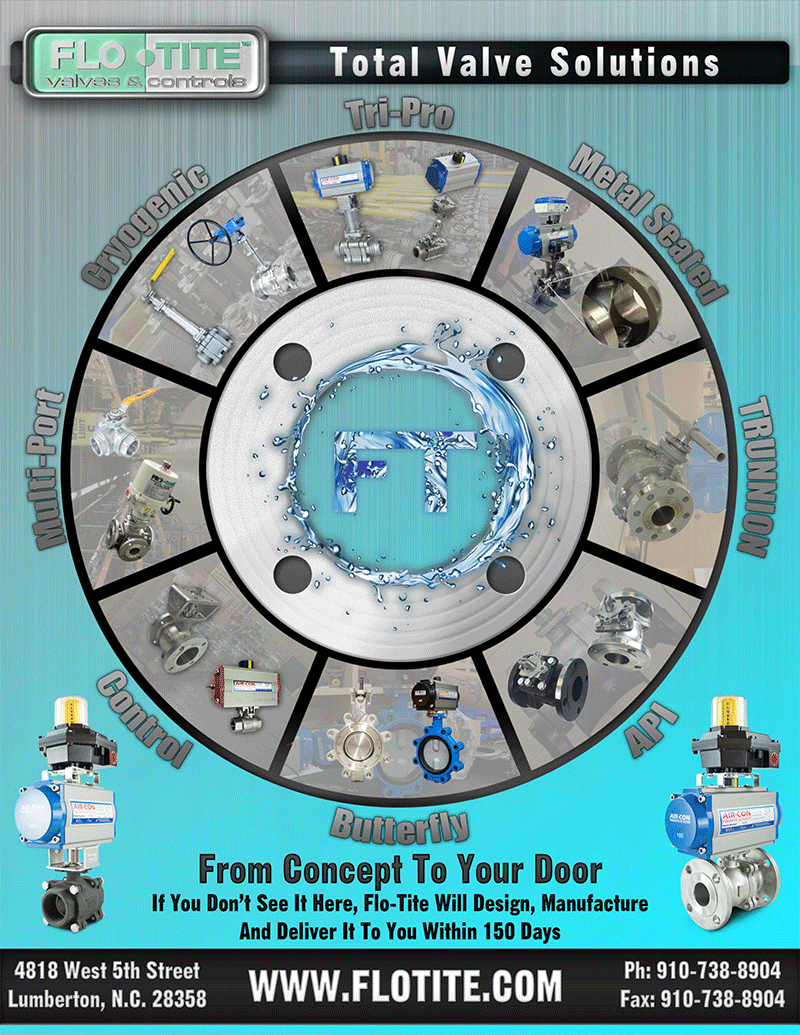

Flo-Tite Valves & Controls 12 million in stock and growing

Flo Tite’s Valves and Controls New Ball Valves and Control Valves

Max Seal Butterfly Valve Manufacturing

Flo-Tite Valves & Controls 12 million in stock and growing

F150 DN15 0

DA105 Actuator

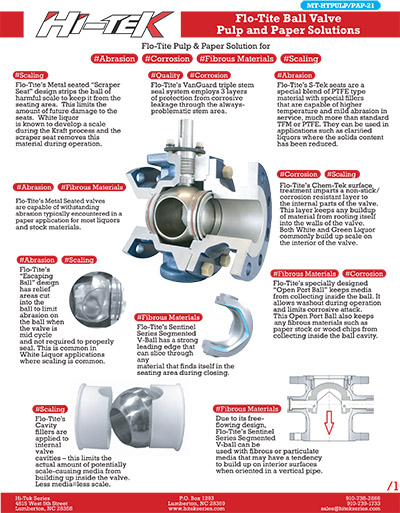

Cavity Filler on Flanged Valve

Flo-Tite Valves & Controls Segmented Ball Valve

Flo-Tite Valves & Controls Universal Mounting Kit

Max Seal and Flo-Tite’s High Performance Butterfly Valve Assembly

Flo-Tite Valves and Controls

FloTite Inc and Martin Gibbons at the Chem Show 2011

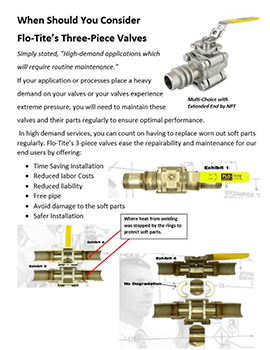

How to Install Repair Kit to Change Seats on 3 PC Ball Valve Flo-Tite

WeldIn-Place Ball Valves- No Disassembly! – Flo-Tite Process Control Solutions

FLO-TITE Valves and Controls TRI-PRO Series

Flo-Tite’s Air-Con Actuator converted from Video Fail Close to Fail Open

FLOTITE F150 IOM

Cavity Filler on Flanged Valve

Max Seal and Flo-Tite’s High Performance Butterfly Valve Assembly

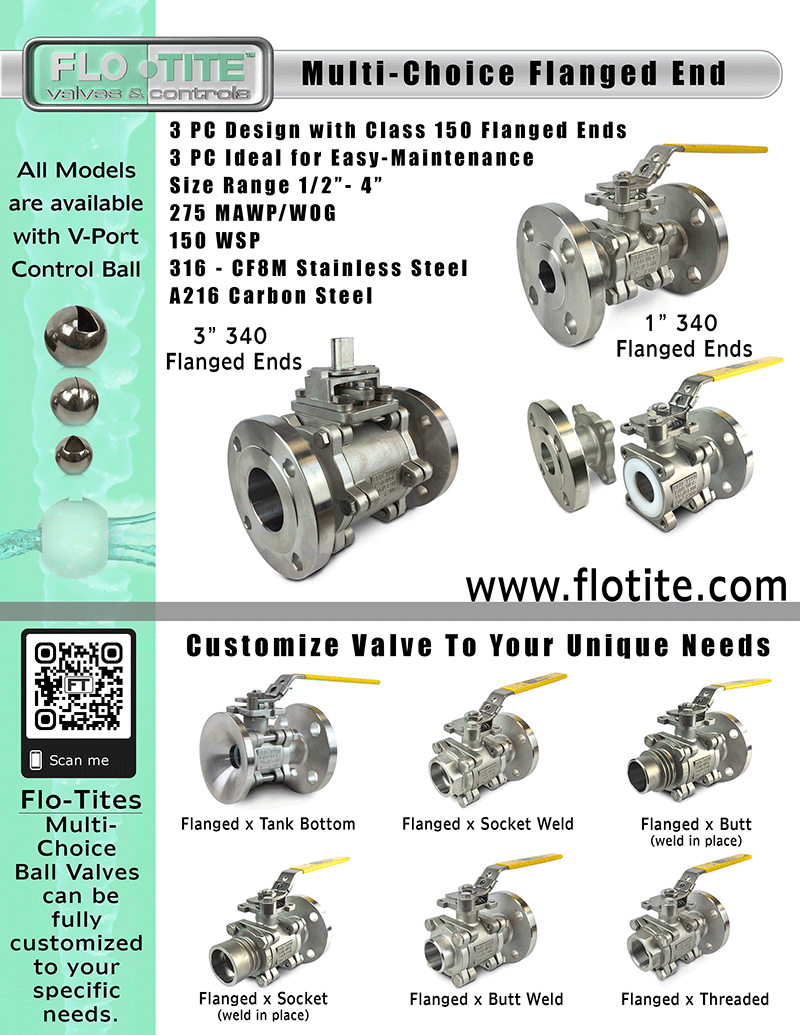

FLOTITE MultiChoiceWeldInPlace

FLOTITE TRI Pro

FLOTITE TITAN

FLOTITE MultiChoiceWeldInPlace

FLOTITE TRI Pro

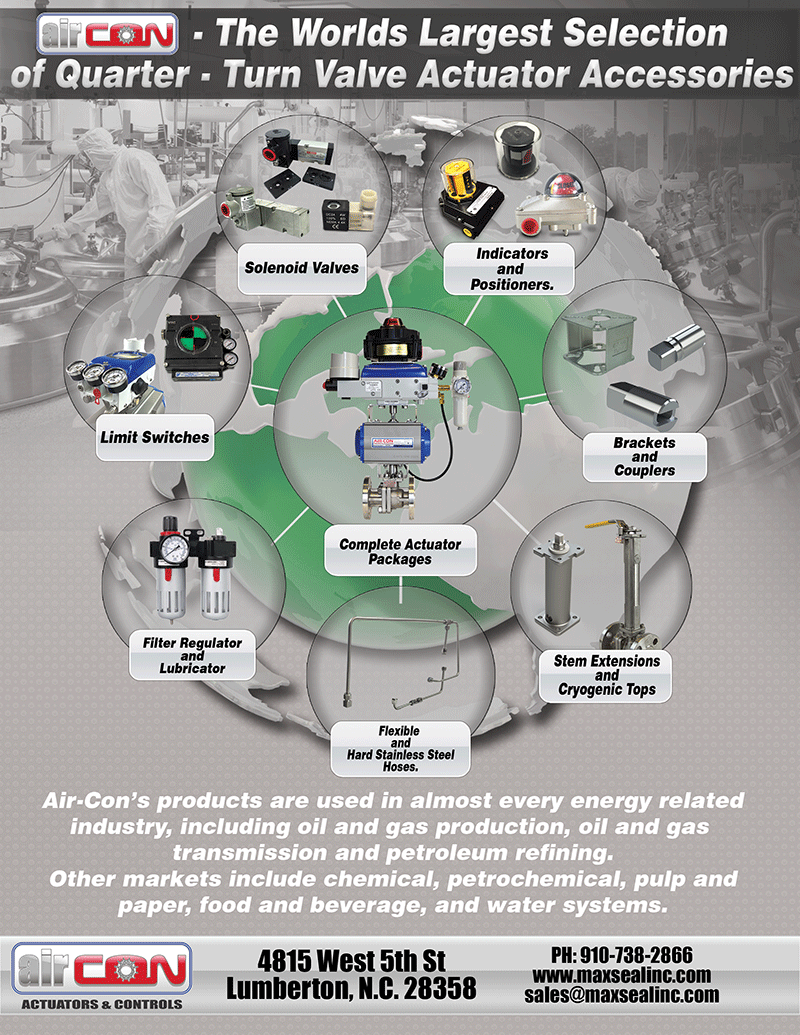

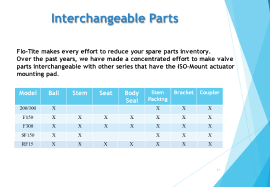

Universal mounting kits suit various valve sizes at reasonable prices.

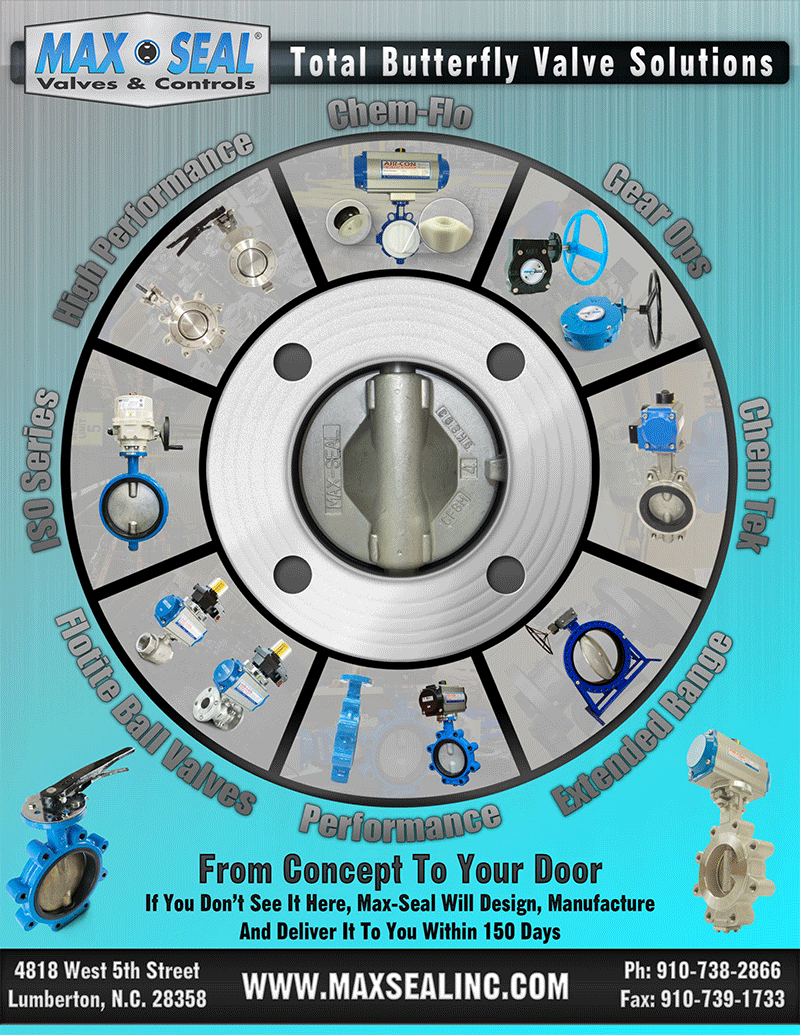

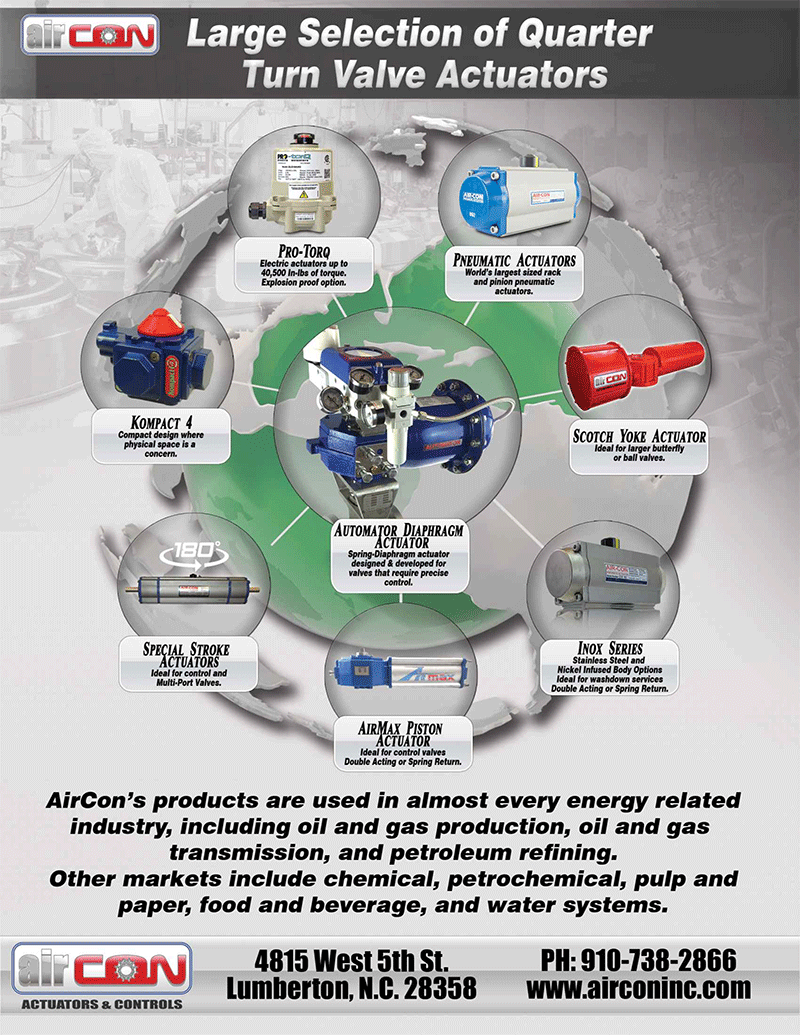

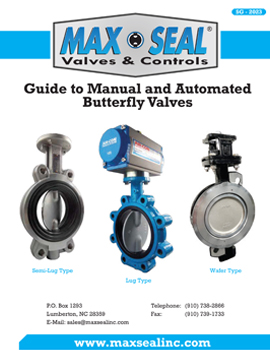

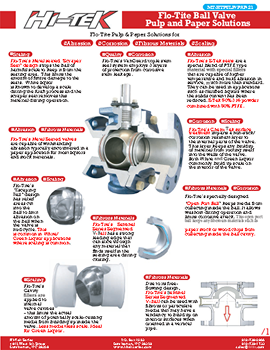

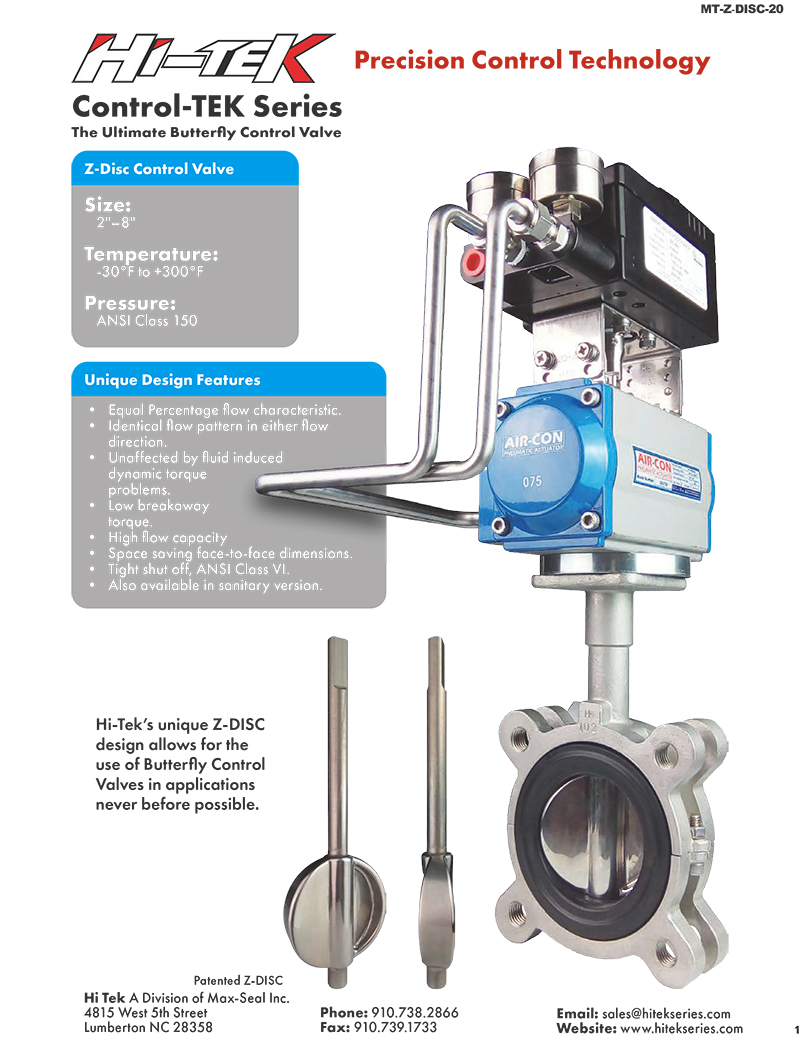

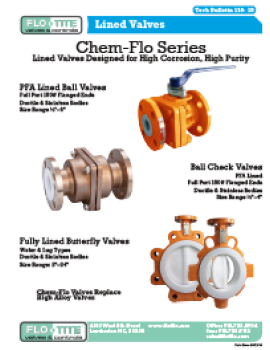

MaxSeal Butterfly Series

MaxSeal Chem Tek Series

API Valve Standards Defined

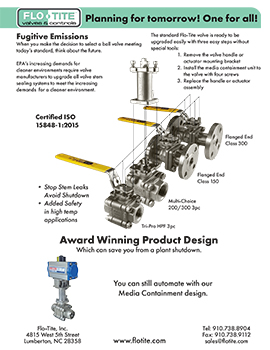

API 641

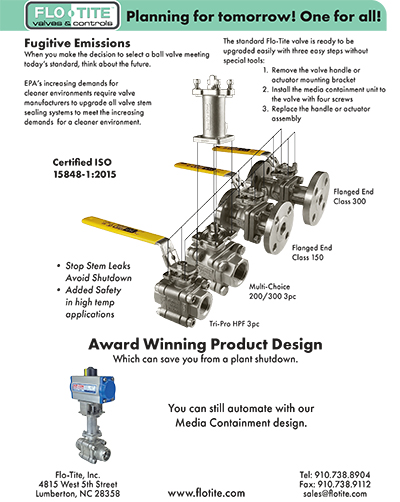

This specifies the allowable amount of fugitive emissions a quarter turn valve is allowed to expel. API 641 standard applies to all stem seal materials and dictates a stringent maximum allowable leakage of 100 parts per million by volume (ppmv). This API test standard calls for 610 mechanical cycles, as well as 3 thermal cycles to evaluate emissions performance over the expected five-year life of the valve.

API 607

This standard specifies Fire Testing of Soft-Seated Quarter Turn Valves. This standard covers the requirements for testing and evaluating the performance of soft-seated quarter-turn valves when the valves are exposed to certain fire conditions defined in this standard. The procedures described in this standard apply to all classes and sizes of Quarter Turn Valves that are made of materials listed in ASME B16.34.

API SPEC 6D

Specifies standards for Pipeline Valves. API Specification 6D is an adoption of ISO 14313: 1999, Petroleum and Natural Gas Industries-Pipeline Transportation Systems-Pipeline Valves. This International Standard specifies requirements for the design, manufacturing, testing and documentation of ball, check, gate and plug valves for applications in pipeline systems.

API 6FA

Specification for Fire Testing Valves. The standard covers the requirements for testing and evaluating the performance of API Spec 6A and Spec 6D valves when exposed to specifically defined fire conditions.

API 609

This specifies Butterfly Valves: Lug, and Wafer designs and Double Flanged designs. The standard covers face-to-face dimensions, materials, design, pressure and temperature ratings, examination, inspection, and test requirements for ductile iron, gray iron, bronze, steel, nickel-base alloys, or special alloy butterfly valves that have tight shutoffs while in the closed position and are suitable for flow regulation.

ANSI/API 608

This specifies Metal Ball Valves with Flanged and Butt-Weld Ends. The standard covers Class 150 and Class 300 metal ball valves that have either butt-weld or flanged ends and are used in on-off services.

API 602

This specifies Compact Steel Gate Valves which are Flanged, Threaded, Weld, and Extended-Body Ends. The standard covers threaded ends, socket weld ends, butt weld ends, and flanged ends encompassing compact carbon steel gate valves in sizes NPS4 and smaller.

API 600

This specifies Bolted Bonnet Steel Gate Valves for Petroleum and Natural Gas Industries – Modified National Adoption of ISO 10434:1998.

API 603

This specifies Corrosion Resistance of Flanged and Butt Welded Ends and Bolted Bonnet Gate Valves. The standard covers corrosion-resistant bolted bonnet gate valves with flanged or butt weld ends in sizes NPS 1/2 – 24, corresponding to nominal pipe sizes in ASME B36.10M, and Classes 150, 300, and 600, as specified in ASME B16.34.

API 599

Specifies Metal Plug Valves in Flanged, Threaded and Welded End designs. A purchase specification that covers requirements for metal plug valves with flanged or butt-welding ends, and ductile iron plug valves with flanged ends, in sizes NPS 1 through NPS 24, which corresponds to nominal pipe sizes in ASME B36.10M. Valve bodies conforming to ASME B16.34 may have one flanged end and one butt weld end. It also covers both lubricated and nonlubricated valves that have two-way coaxial ports, and includes requirements for valves fitted with internal body, plug, or port linings or applied hard facings on the body, body ports, plug, or plug port.

API 598

This specifies Valve Inspection and Testing standards. The standard covers inspection, supplementary examination, and pressure test requirements for both resilient-seated and metal-to-metal seated ball valves, check valves, butterfly valves. gate valves, globe valves, and plug valves. It specifies inspection by the purchaser and to any supplementary examinations the purchaser may require at the valve manufacturer’s plant.

API STD 594

This specifies standards for Check Valves in Flanged, Lug, Wafer and Butt-Weld designs. API Standard 594 covers design, material, face-to-face dimensions, pressure and temperature ratings, and examination, inspection, and test requirements for two types of check valves.

![MaxSeal Upgrade Bulletin R6[1863]](https://flotitevalve.treffertech.com/wp-content/uploads/2023/12/MaxSeal-Upgrade-Bulletin-R61863.jpg)